Kreg Jig Cabinet Door Hinge Installation Techniques

Installing cabinet door hinges can be a frustrating task, but the Kreg Jig system simplifies the process significantly, offering precision and speed. This guide will explore various techniques for using a Kreg Jig to achieve professional-looking results every time. We’ll cover different methods, troubleshooting common problems, and provide a visual guide to ensure your hinges are perfectly aligned.

Step-by-Step Guide for Kreg Jig Cabinet Door Hinge Installation

Precise hinge placement is crucial for a perfectly functioning cabinet door. Following these steps ensures accuracy and minimizes frustration.

- Mark Hinge Location: Carefully measure and mark the exact location of the hinges on both the cabinet door and the cabinet face. Use a pencil to lightly mark the hinge positions, ensuring consistent spacing between hinges.

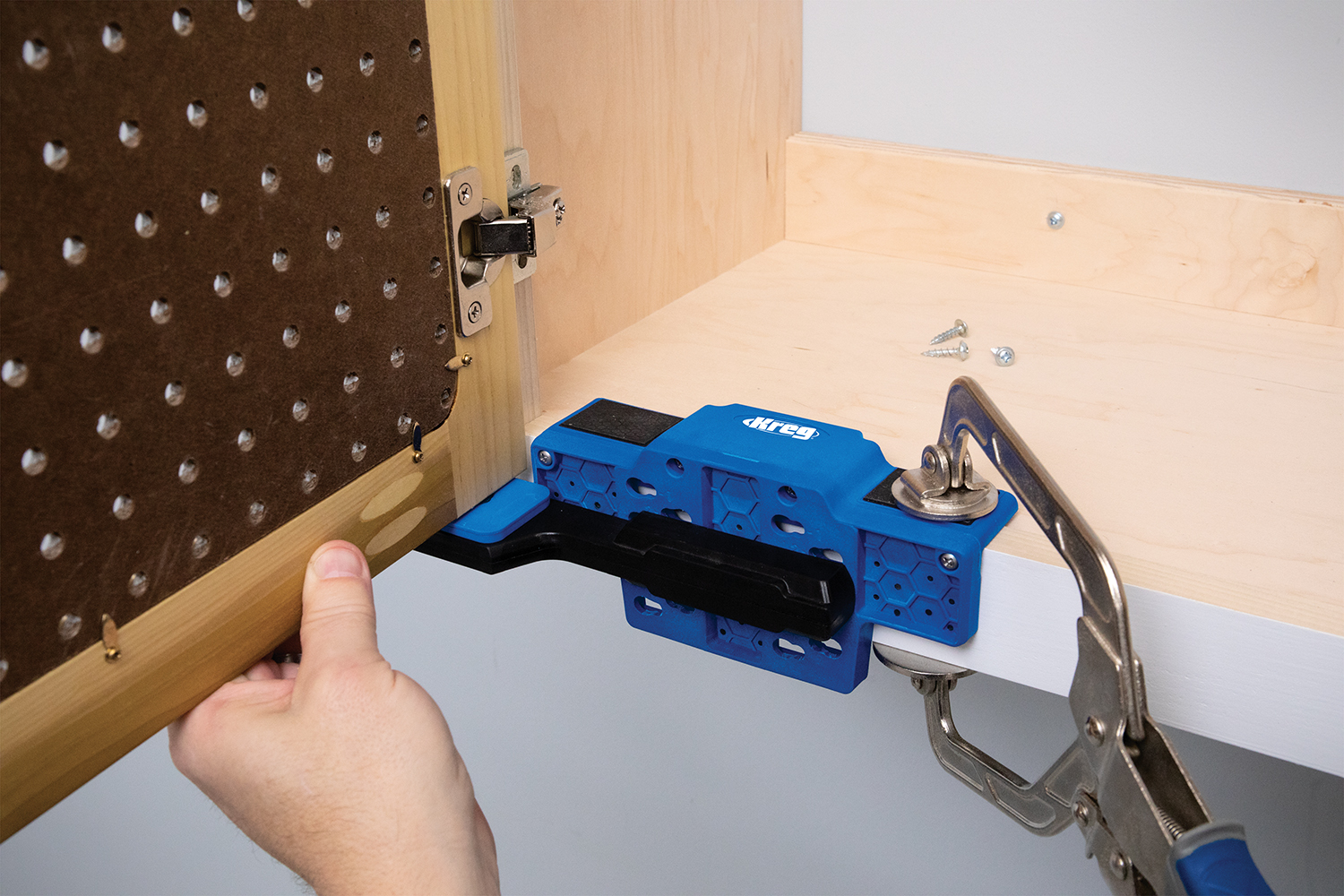

- Set Up the Kreg Jig: Select the appropriate Kreg Jig bit for your hinge size. Ensure the jig is securely clamped to the cabinet door or cabinet face, aligning the bit with your pencil marks. Proper clamping is vital for accurate drilling.

- Drill Pilot Holes: Slowly and carefully drill pilot holes at the marked locations using the Kreg Jig. Avoid excessive pressure to prevent the bit from wandering or damaging the wood.

- Install the Hinges: Align the hinges with the pilot holes and carefully screw them into place. Use a screwdriver that matches the screw size to avoid stripping the screw heads. Do not overtighten the screws.

- Check Alignment: Once the hinges are installed, open and close the cabinet door to check for proper alignment. Make adjustments if necessary.

Comparison of Kreg Jig Hinge Installation Methods

Three primary methods exist for using a Kreg Jig to install cabinet hinges, each with its advantages and disadvantages.

| Method | Advantages | Disadvantages | Time Required |

|---|---|---|---|

| Using the Jig for Pilot Holes Only | Faster, less precise measurements needed. | Requires separate hinge placement marking. Slightly higher chance of misalignment. | 10-15 minutes per door |

| Using the Jig for Both Pilot Holes and Hinge Placement | More precise, less chance of misalignment. | Requires more precise measurements and jig setup. Slightly slower. | 15-20 minutes per door |

| Using the Jig with a Hinge Template | Most accurate and consistent results. Fastest method for multiple doors. | Requires a specialized hinge template. Higher initial investment. | 8-12 minutes per door (after initial setup) |

Visual Representation of Proper Hinge Placement

Imagine a diagram showing a cabinet door and face. The Kreg Jig is clamped to the door, its bit precisely aligned with a pencil mark indicating the hinge location. A second mark on the cabinet face, aligned with the first, indicates the corresponding hinge location. The jig ensures both marks are perfectly aligned vertically and horizontally, resulting in perfectly aligned hinges. The diagram would clearly show the pilot holes created by the jig, and the hinges precisely seated in these holes.

Troubleshooting Common Kreg Jig Installation Issues

Even with a Kreg Jig, problems can arise. Here’s how to address them.

- Misaligned Hinges: Recheck your measurements and ensure the Kreg Jig is properly clamped and aligned before drilling. If the hinges are slightly misaligned, carefully remove them and re-install, paying close attention to alignment.

- Stripped Screw Holes: Use the correct size screwdriver bit and avoid over-tightening the screws. If screw holes are stripped, consider using wood glue and toothpicks to fill the holes, allowing them to dry completely before re-drilling and installing new screws.

- Inconsistent Depth: Ensure that the depth setting on the Kreg Jig is correctly adjusted for the thickness of your door and cabinet face. Inconsistent depth can lead to uneven hinge placement and door misalignment.

Choosing the Right Kreg Jig and Hardware for Cabinet Doors

Selecting the correct Kreg Jig and accompanying hardware is crucial for a successful and durable cabinet door hinge installation. The right tools and materials ensure a precise fit, strong hold, and a professional finish. Choosing poorly can lead to wobbly doors, stripped wood, and frustrating rework. Let’s explore the options available to you.

Kreg Jig Options for Cabinet Door Hinge Installation, Kreg jig cabinet door hinge

The choice of Kreg Jig depends largely on the frequency of use and the type of projects you undertake. While several models exist, a few stand out as particularly suitable for cabinet door hinge installations.

- Kreg Jig R3: This is a popular choice for its versatility and ease of use. It’s suitable for a wide range of woodworking projects, including cabinet doors, and offers precise pocket hole drilling for strong joinery. The clamping mechanism is robust, ensuring accurate placement of the holes.

- Kreg Jig K4 Master System: A more advanced system, the K4 offers greater adjustability and includes multiple drilling guides for various applications. Its larger capacity makes it ideal for larger cabinet doors or multiple projects. The built-in depth adjustment makes it very precise.

- Kreg Jig Micro-Jig: Designed for smaller projects and delicate work, the Micro-Jig is perfect for smaller cabinet doors or intricate joinery where precise placement is critical. While less powerful than the R3 or K4, its compact size makes it maneuverable in tight spaces.

Cabinet Door Hinge Specifications

Different hinges offer varying features impacting strength, style, and suitability for specific cabinet types. Understanding these differences is key to choosing the right hinge.

| Hinge Type | Material | Size (example) | Weight Capacity (example) |

|---|---|---|---|

| Full Overlay Hinge | Steel | 35mm | 25 lbs |

| Half Overlay Hinge | Zinc Alloy | 26mm | 15 lbs |

| Inset Hinge | Steel | 35mm | 30 lbs |

| European Hinge | Steel | Variable, depends on cup size | Variable, depends on cup size and hinge design |

Screw Selection for Hinge Installation

The screws you choose significantly impact the strength and longevity of your hinge installation. Using the wrong screws can lead to stripped wood, loose hinges, and ultimately, door failure.

- Screw Type: Use screws specifically designed for wood. Phillips head or square drive screws are common choices, offering good grip and resistance to cam-out (the screw slipping out of the driver). Avoid using drywall screws or other inappropriate screw types.

- Screw Length: The screw length should be carefully chosen to ensure sufficient penetration into the cabinet door and frame without protruding through the other side. A general rule is to have the screw penetrate at least ¾ inch into the wood. Always pre-drill pilot holes to prevent wood splitting.

- Screw Material: Steel screws offer good strength and durability. For increased corrosion resistance in damp environments, consider stainless steel screws.

Kreg Jig Bit Selection Guide

The correct Kreg Jig bit is essential for creating perfectly sized pocket holes that align with your chosen hinges. Using the wrong bit can result in misaligned hinges or damaged wood.

Kreg jig cabinet door hinge – Imagine a set of Kreg Jig bits, each clearly labeled with its corresponding size. Each bit has a specific diameter, allowing for precise pocket hole creation. A visual representation would show the bits neatly arranged, each with its size clearly marked. One bit, for instance, might be clearly labeled as suitable for #6 screws, another for #8 screws, and so on, with accompanying images depicting the appropriate sized pocket hole and screw in relation to the bit.

Advanced Techniques and Applications of Kreg Jigs with Cabinet Door Hinges: Kreg Jig Cabinet Door Hinge

Mastering the Kreg Jig for cabinet door hinge installation opens up a world of possibilities beyond basic applications. This section delves into advanced techniques, allowing you to tackle complex hinge types and even repair damaged installations with precision and ease. We’ll explore how to adapt the jig for various hinge styles and create custom solutions for unique door designs.

Installing Different Types of Cabinet Door Hinges

The Kreg Jig’s versatility shines when installing various cabinet door hinge types. Proper jig adjustment is crucial for achieving accurate placement and a perfect fit, regardless of whether you’re working with overlay, inset, or full overlay hinges. Slight variations in drilling depth and placement are needed to accommodate each hinge type’s unique design and mounting requirements.

- Overlay Hinges: These hinges are partially concealed, with the door overlapping the cabinet face. The Kreg Jig’s standard settings often work well, but precise depth is crucial to avoid drilling too deep and compromising the cabinet’s structural integrity. The hinge cup should be flush or slightly recessed.

- Inset Hinges: Inset hinges are fully concealed, with the door sitting within the cabinet frame. This requires precise measurements and potentially adjustments to the Kreg Jig’s depth stop to create a mortise that perfectly accommodates the hinge cup without compromising the door’s flush fit within the cabinet opening. A slight countersink might be needed for a perfect aesthetic.

- Full Overlay Hinges: These hinges completely cover the cabinet face when the door is closed. The Kreg Jig needs to be adjusted to create a mortise that allows for the hinge to sit flush with the door’s edge while providing sufficient clearance for the door to open and close smoothly. Precise placement is critical for a seamless look.

Creating Custom Cabinet Door Hinge Mortises

The Kreg Jig isn’t limited to standard hinge placements. Its precision allows for creating custom mortises for uniquely shaped or sized cabinet doors. This opens the door to truly personalized cabinetry.

- Measure and Mark: Carefully measure the hinge’s dimensions and mark the desired location on the door. Remember to account for the door’s thickness and the hinge’s leaf size.

- Create a Template: If the hinge requires a non-standard mortise shape, create a template from sturdy material like plywood. This template will guide the drilling process.

- Drill Pilot Holes: Using the template (if needed) and the Kreg Jig, drill pilot holes to guide the larger bit. This ensures accuracy and prevents the bit from wandering.

- Create the Mortise: Carefully enlarge the pilot holes to the desired mortise size using a suitable router bit or chisel. Multiple passes might be needed for larger mortises. A template is crucial for consistent results with complex shapes.

- Test Fit: Before fully installing the hinge, test fit it into the mortise to ensure a snug and secure fit. Adjust as needed.

Repairing Damaged Cabinet Door Hinge Holes

Even with careful installation, hinge holes can become damaged over time. The Kreg Jig offers a clever solution for repairing these damaged areas and restoring the door’s functionality.

- Assess the Damage: Carefully examine the damaged hinge hole. Determine the extent of the damage to decide the best repair strategy. This may involve filling the hole, creating a new mortise nearby, or using wood filler to reinforce the existing hole.

- Prepare the Area: Clean the damaged area and remove any loose wood fragments. If necessary, use wood filler to reinforce the damaged area, allowing it to dry completely.

- Create a New Mortise (if needed): If the damage is extensive, create a new mortise slightly offset from the original, using the Kreg Jig and appropriate drill bits. Ensure the new mortise is properly sized and aligned for the hinge.

- Install the Hinge: Once the repair is complete, install the hinge into the repaired or new mortise, ensuring a snug and secure fit.